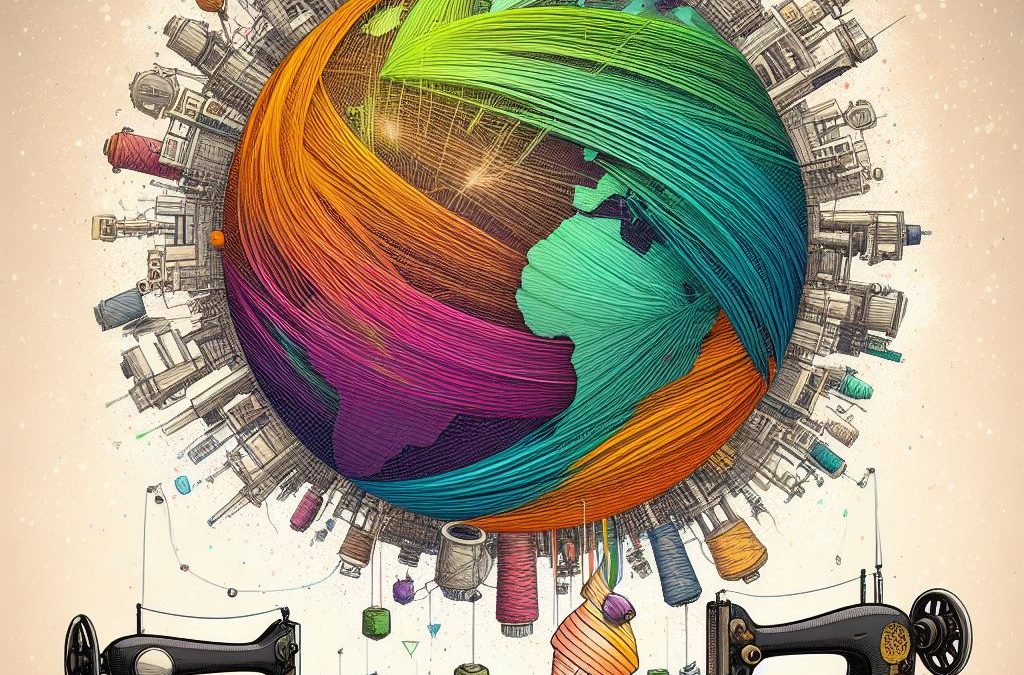

The apparel industry in Bangladesh has been a cornerstone of the nation’s economic growth for decades. Tracing its origins back to the 1970s, the ready-made garment (RMG) sector began as a small industry with limited reach. However, over the years, it has metamorphosed into a global powerhouse, propelling Bangladesh to the forefront of apparel manufacturing worldwide.

Historically, the industry’s growth can be attributed to several factors. One of the major catalysts was the Multi Fibre Arrangement (MFA) in the 1970s and 1980s, which imposed quotas on garment exports from established markets, steering international buyers towards newer markets, including Bangladesh. This provided an initial impetus for local entrepreneurs to invest in garment manufacturing.

In addition to external market conditions, the internal dynamics of Bangladesh played a significant role. The availability of a vast labor pool, combined with low labor costs, presented an attractive proposition for businesses. This advantage was further complemented by the entrepreneurial spirit of the Bangladeshi business community, which was quick to seize the opportunity and establish manufacturing units.

Fast forward to the present day, and the apparel industry in Bangladesh is a force to be reckoned with. It accounts for over 80% of the nation’s export earnings, employing millions of people, predominantly women. The industry has not only provided livelihoods but has also played a pivotal role in empowering a significant section of the population.

The significance of the apparel industry in the global market cannot be overstated. Bangladesh is currently the second-largest apparel exporter in the world, trailing only behind China. Brands and retailers from around the world source a substantial portion of their products from Bangladesh, testament to the nation’s reliability and expertise in garment manufacturing.

However, this journey hasn’t been without its challenges. From infrastructural bottlenecks to concerns about workers’ rights and safety, the industry has faced numerous hurdles. But each challenge has been met with resilience and adaptability, hallmarks of Bangladesh’s apparel sector.

The industry’s evolution is also characterized by its ability to adapt to changing global demands. As the world shifts towards sustainable and ethical fashion, Bangladeshi manufacturers are making concerted efforts to align their practices with global standards, ensuring a sustainable future for the industry.

In conclusion, the apparel industry in Bangladesh stands as a beacon of economic progress and resilience. From humble beginnings, it has emerged as a global leader, showcasing the nation’s potential and paving the way for future growth and development.

Bangladesh’s Unique Position in the Global Apparel Market

Bangladesh holds a unique and dominant position in the global apparel market, standing out for a myriad of reasons that make it a preferred destination for apparel sourcing:

- Comparative Advantage: In economics, the term ‘comparative advantage’ refers to the ability of a country to produce goods at a lower opportunity cost than another country. Bangladesh’s apparel sector has a distinct comparative advantage primarily due to:

- Low Labor Costs: With one of the lowest wage rates in the world, Bangladesh can produce garments more affordably than many other nations.

- Skilled Workforce: Generations of workers in Bangladesh have been associated with apparel manufacturing, leading to an accumulation of valuable skills and expertise in the field.

- Strategic Geographic Location: Situated between the major markets of the West and the manufacturing powerhouses of the East, Bangladesh’s location makes it ideal for both sourcing raw materials and exporting finished products efficiently.

- Diverse Product Range: Bangladesh is not limited to just one type of garment. The country produces a wide range of products, from basic T-shirts to high-end fashion items, catering to various market segments.

- Capacity to Handle Bulk Orders: The sheer volume of production units and a massive workforce ensures that Bangladesh can handle large orders with ease, making it a reliable source for major international brands.

- Strong Backward Linkage: The growth of the apparel sector in Bangladesh has been complemented by the development of its textile sector, ensuring a steady supply of fabrics and other essential raw materials.

| Key Factors | Description |

|---|---|

| Labor Costs | One of the lowest in the world, making production cost-effective. |

| Workforce | Skilled and experienced in apparel manufacturing. |

| Product Diversity | Capable of producing a wide range of apparel products. |

| Capacity | Ability to handle large, bulk orders efficiently. |

| Raw Materials | Strong backward linkage ensures a steady supply. |

However, it’s important to note that while these factors contribute to Bangladesh’s dominance, they also bring forth challenges. Relying heavily on low labor costs can lead to concerns about workers’ rights and wages. The nation’s apparel sector constantly grapples with the balance between maintaining competitive pricing and ensuring fair practices.

Nevertheless, the global recognition of Bangladesh’s apparel sector is undeniable. As the world becomes more interconnected, the significance of a reliable, efficient, and skilled manufacturing base like Bangladesh becomes even more pronounced.

In the ever-evolving landscape of global trade, Bangladesh’s apparel industry continues to carve out its niche, adapting to changing demands while upholding its unique strengths.

Key Competitive Strategies Adopted

The success of the apparel industry in Bangladesh is not just a product of favorable conditions, but also a result of deliberate and strategic moves made by manufacturers to stay competitive. Here are the key strategies that have been instrumental in the industry’s success:

- Cost Leadership through Efficient Production Techniques: Bangladesh’s apparel sector has been able to maintain its competitive edge primarily because of its focus on cost leadership. This involves:

- Bulk Production: By producing in large quantities, manufacturers benefit from economies of scale, reducing the cost per unit.

- Streamlined Operations: Efficient assembly lines and optimized production processes ensure minimal wastage and faster turnaround times.

- Diversification of Product Lines: Instead of solely focusing on basic clothing items, many manufacturers have branched out into various apparel categories, including sportswear, luxury wear, and specialized garments. This diversification allows them to cater to a broader market and reduce dependency on any single product category.

- Sustainable and Eco-friendly Manufacturing: With growing global consciousness about the environment and sustainability, Bangladeshi manufacturers have been:

- Adopting Green Technologies: Such as solar power, water recycling systems, and eco-friendly dyes.

- Obtaining Certifications: Many factories have sought and obtained international certifications like LEED (Leadership in Energy and Environmental Design) to showcase their commitment to sustainable practices.

- Investing in Technology and Automation: The future of manufacturing lies in technology. Recognizing this, Bangladeshi manufacturers have:

- Incorporated Automated Machinery: For tasks like cutting, sewing, and finishing to improve precision and speed.

- Utilized Data Analytics: To forecast trends, optimize supply chains, and enhance overall operational efficiency.

- Building Strong Relationships with International Buyers: Trust and reliability are crucial in the global apparel market. Manufacturers in Bangladesh have made concerted efforts to:

- Participate in International Trade Fairs: This allows them to showcase their capabilities and network with potential buyers.

- Ensure Quality and Compliance: Regular audits, quality checks, and adherence to international standards have made Bangladeshi manufacturers a preferred choice for many global brands.

| Strategy | Key Components |

|---|---|

| Cost Leadership | Bulk production, streamlined operations |

| Product Diversification | Expanding into various apparel categories |

| Sustainability | Green technologies, international certifications |

| Technology and Automation | Automated machinery, data analytics |

| Relationship Building | Trade fairs participation, ensuring quality and compliance |

These strategies are not static; they evolve in response to the dynamic global market and emerging challenges. By staying agile, forward-thinking, and adaptive, the apparel industry in Bangladesh continues to solidify its position on the global stage.

Case Studies of Leading Apparel Manufacturers

Success in the apparel industry isn’t solely about numbers or production capacity. It’s also about the ingenuity, resilience, and innovation of individual manufacturers. Let’s delve into a few case studies that showcase the success stories of top brands from Bangladesh and the innovative strategies they’ve implemented:

1. Brand A: Pioneers in Sustainability

Brand A has been a trailblazer in sustainable apparel manufacturing in Bangladesh. Key highlights of their journey include:

- Eco-friendly Infrastructure: Their factories are designed with energy conservation in mind, utilizing natural light and efficient insulation.

- Water Conservation: They’ve implemented state-of-the-art water recycling systems, reducing their consumption and ensuring minimal wastage.

- Partnerships for Sustainability: Collaborating with international organizations, they’ve embarked on projects to further reduce their carbon footprint.

2. Brand B: Technology Front-runners

With a focus on harnessing the power of technology, Brand B has set new benchmarks in apparel manufacturing:

- Automated Production Lines: They’ve integrated robotics into their assembly lines, ensuring precision and consistency in production.

- Digital Trend Forecasting: Leveraging big data analytics, they accurately predict fashion trends, optimizing their production cycle.

- Virtual Sampling: Instead of producing physical samples, they’ve adopted 3D design software, saving both time and resources.

3. Brand C: Diversification Masters

Brand C showcases the power of product diversification in the apparel industry:

- Expansive Product Line: From casual wear to specialized sportswear, they cater to a wide range of market segments.

- In-house Design Teams: By having dedicated design teams, they’re able to quickly adapt to changing fashion trends.

- Global Reach: They’ve established distribution networks in multiple continents, ensuring their products are accessible to a global audience.

4. Brand D: Workers’ Well-being Champions

Prioritizing the welfare of their workforce, Brand D stands as a testament to responsible manufacturing:

- Worker Training Programs: They regularly conduct training sessions, enhancing the skills of their employees.

- Health and Safety: Ensuring a safe working environment, they’ve minimized workplace accidents and fostered a culture of safety.

- Community Initiatives: Beyond the factory, they’ve initiated community development projects, uplifting the regions they operate in.

| Brand | Unique Strategy |

|---|---|

| Brand A | Pioneering sustainable practices |

| Brand B | Embracing technological advancements |

| Brand C | Mastering product diversification |

| Brand D | Prioritizing workers’ well-being |

These case studies underscore the multifaceted strategies employed by leading apparel manufacturers in Bangladesh. While each brand has its unique approach, the common thread is innovation, adaptability, and a commitment to excellence.

Challenges and How They Are Overcome

The journey of Bangladesh’s apparel industry to global prominence hasn’t been a smooth one. The sector has faced its fair share of challenges. However, the resilience and adaptability demonstrated by manufacturers and stakeholders have been instrumental in overcoming these hurdles. Here’s a closer look:

1. Overcoming Infrastructural Challenges:

Bangladesh, being a developing country, has faced infrastructural bottlenecks that could potentially impede the growth of the apparel sector.

- Development of Special Economic Zones (SEZs): The government and private sector have collaborated to establish SEZs, providing manufacturers with the necessary infrastructure and facilities to operate efficiently.

- Investment in Transport: Efforts have been made to improve road, rail, and port facilities, ensuring timely movement of goods.

2. Addressing Workers’ Rights and Safety Issues:

The industry has been under scrutiny, especially after tragic incidents like the Rana Plaza collapse.

- Implementation of Safety Protocols: Post such incidents, there’s been a concerted effort to ensure factories comply with international safety standards.

- Formation of Workers’ Unions: Workers are now more empowered to voice their concerns and negotiate for better working conditions.

3. Navigating International Trade Barriers:

Trade restrictions and tariffs can be a significant challenge for exporters.

- Diversifying Export Destinations: To reduce dependency on a single market, manufacturers have expanded their reach to newer regions.

- Lobbying and Diplomacy: The Bangladeshi government and trade bodies actively engage with international counterparts to negotiate favorable trade terms.

4. Maintaining Competitive Pricing:

With rising costs and competition, maintaining an edge in pricing can be challenging.

- Investment in Technology: By automating certain processes, manufacturers can reduce costs and improve efficiency.

- Vertical Integration: Many manufacturers have integrated backward and forward, controlling every stage of production and thereby optimizing costs.

5. Adapting to Changing Consumer Preferences:

The global consumer is becoming more conscious about sustainability and ethical manufacturing.

- Sustainable Manufacturing: As discussed earlier, many factories are moving towards eco-friendly practices.

- Transparency and Traceability: Brands are focusing on ensuring consumers can trace the origins of their products, fostering trust.

| Challenge | Solution |

|---|---|

| Infrastructural Issues | Development of SEZs, improved transport |

| Workers’ Rights | Safety protocols, workers’ unions |

| Trade Barriers | Diversifying exports, diplomacy |

| Pricing | Technology, vertical integration |

| Consumer Preferences | Sustainable practices, transparency |

While challenges persist, the continuous efforts by all stakeholders, from factory workers to policymakers, ensure that the Bangladeshi apparel sector remains resilient and continues its upward trajectory.

The Role of Government and Policy Support

The meteoric rise of Bangladesh’s apparel industry is not just the result of entrepreneurial endeavors and market dynamics. The role of government policies and strategic interventions has been pivotal in shaping the industry’s trajectory. Here’s a deeper look into the support mechanisms put in place:

1. Incentives Provided by the Government:

To bolster the growth of the apparel sector, the government has provided a range of incentives.

- Tax Holidays: New enterprises in the apparel sector often benefit from tax holidays for a certain period, reducing their financial burden.

- Duty Drawback: Exporters receive a refund on the import duties they’ve paid on raw materials, making exports more competitive.

2. Export Policies and Their Impact:

A favorable export policy framework has been instrumental in facilitating the growth of apparel exports.

- Simplified Export Procedures: The government has streamlined export procedures, making it easier for manufacturers to access global markets.

- Export Processing Zones (EPZs): These zones provide manufacturers with world-class infrastructure and facilities, coupled with regulatory benefits, to promote exports.

3. Skill Development Initiatives:

Recognizing the need for a skilled workforce, the government has launched various programs.

- Training Centers: In collaboration with industry bodies, the government has set up training centers to enhance the skills of workers in the apparel sector.

- Collaborations with International Bodies: Partnerships with international organizations ensure that training is in line with global standards.

4. Infrastructure Development:

Infrastructure is the backbone of any industry, and the apparel sector is no exception.

- Upgradation of Ports: To facilitate exports, significant investments have been made to upgrade sea and air ports.

- Improved Road Connectivity: Efforts are underway to improve road connectivity between production hubs and ports, reducing transit times.

5. Promotion of Sustainable Practices:

With global focus shifting towards sustainability, the government is promoting green initiatives.

- Subsidies for Green Technology: Manufacturers adopting green technologies often receive financial incentives and subsidies.

- Awards and Recognition: The government recognizes and awards factories that demonstrate excellence in sustainable manufacturing, incentivizing others to follow suit.

| Government Initiative | Description |

|---|---|

| Incentives | Tax holidays, duty drawback |

| Export Policies | Simplified procedures, EPZs |

| Skill Development | Training centers, global collaborations |

| Infrastructure | Ports upgradation, road connectivity |

| Sustainability | Green tech subsidies, awards |

The synergy between the government’s vision and the industry’s aspirations has created a conducive environment for the apparel sector’s growth. Through continuous policy interventions and support mechanisms, the government of Bangladesh has played an indispensable role in the industry’s success story.

Future Prospects and Trends

The dynamic nature of the apparel industry demands constant evolution. As Bangladesh’s apparel sector looks to the future, several prospects and trends are emerging that will shape its trajectory:

1. Shift Towards Sustainable Fashion:

As global consumers become more eco-conscious, there’s a growing demand for sustainable fashion.

- Eco-friendly Materials: The use of organic cotton, recycled polyester, and other sustainable materials is on the rise.

- Zero Waste Production: Manufacturers are exploring techniques to minimize wastage during the production process.

2. Integration of Technology in Manufacturing:

The future of apparel manufacturing will be heavily intertwined with technology.

- Smart Factories: The concept of Industry 4.0, where machines, devices, and humans communicate and collaborate, is becoming a reality in some advanced factories.

- AI and Data Analytics: Predictive analytics, driven by artificial intelligence, will play a pivotal role in trend forecasting and inventory management.

3. Expanding into New Markets:

While the West remains a major market for Bangladeshi apparel, there’s a push to explore newer markets.

- South and Southeast Asia: With rising incomes, countries like India, Indonesia, and Vietnam offer lucrative markets.

- Africa: The African continent, with its growing youth population and increasing purchasing power, is seen as a potential market.

4. Personalized and Customized Fashion:

The era of mass-produced fashion is giving way to personalized and customized offerings.

- On-demand Manufacturing: With advancements in technology, the idea of producing apparel on-demand, based on specific customer preferences, is gaining traction.

- 3D Printing: Technologies like 3D printing can revolutionize the way apparel is designed and produced, allowing for high levels of customization.

5. E-commerce and Digital Transformation:

The digital revolution is reshaping the apparel industry.

- Direct-to-Consumer (DTC) Models: More manufacturers are exploring DTC models, bypassing traditional retail channels and selling directly to consumers through online platforms.

- Virtual Try-Ons: Augmented Reality (AR) is enabling consumers to virtually try on clothes before purchasing, enhancing the online shopping experience.

| Future Trend | Implications |

|---|---|

| Sustainable Fashion | Eco-friendly materials, waste reduction |

| Technology | Smart factories, AI-driven analytics |

| New Markets | Asia, Africa |

| Personalization | On-demand manufacturing, 3D printing |

| Digital Transformation | DTC models, AR try-ons |

As the apparel industry in Bangladesh navigates these emerging trends, its adaptability and innovative spirit will be crucial. While challenges will undoubtedly arise, the prospects for continued growth and evolution are promising.

Conclusion

The apparel industry in Bangladesh stands as a testament to the nation’s resilience, adaptability, and entrepreneurial spirit. As we’ve explored throughout this piece, the industry’s journey from humble beginnings to global prominence has been marked by strategic decisions, innovation, and an unwavering commitment to excellence. With the world becoming more interconnected and the demands of the global consumer constantly evolving, Bangladesh’s apparel manufacturers are poised to not only meet these challenges but also redefine industry standards.

For those in search of a reliable partner in the apparel industry, look no further than Brandex Sourcing. At Brandex Sourcing, we pride ourselves on our commitment to quality control, affordability, punctuality, and above all, an ethical approach that prioritizes both the environment and the well-being of our workers. If you’re interested in exploring how we can assist you in your apparel manufacturing needs, we invite you to reach out to us for a quote.

As the global apparel landscape continues to evolve, Bangladesh remains a beacon of innovation and growth. And at Brandex Sourcing, we are proud to be a part of this illustrious journey.